Have you ever wondered why your chocolate melts so smoothly or maintains that perfect glossy finish? The answer often lies in a specialized food additive called PGPR. Understanding this ingredient helps consumers make informed choices about what goes into their favorite treats while appreciating the science behind modern food production.

What Exactly Is PGPR in Food Production?

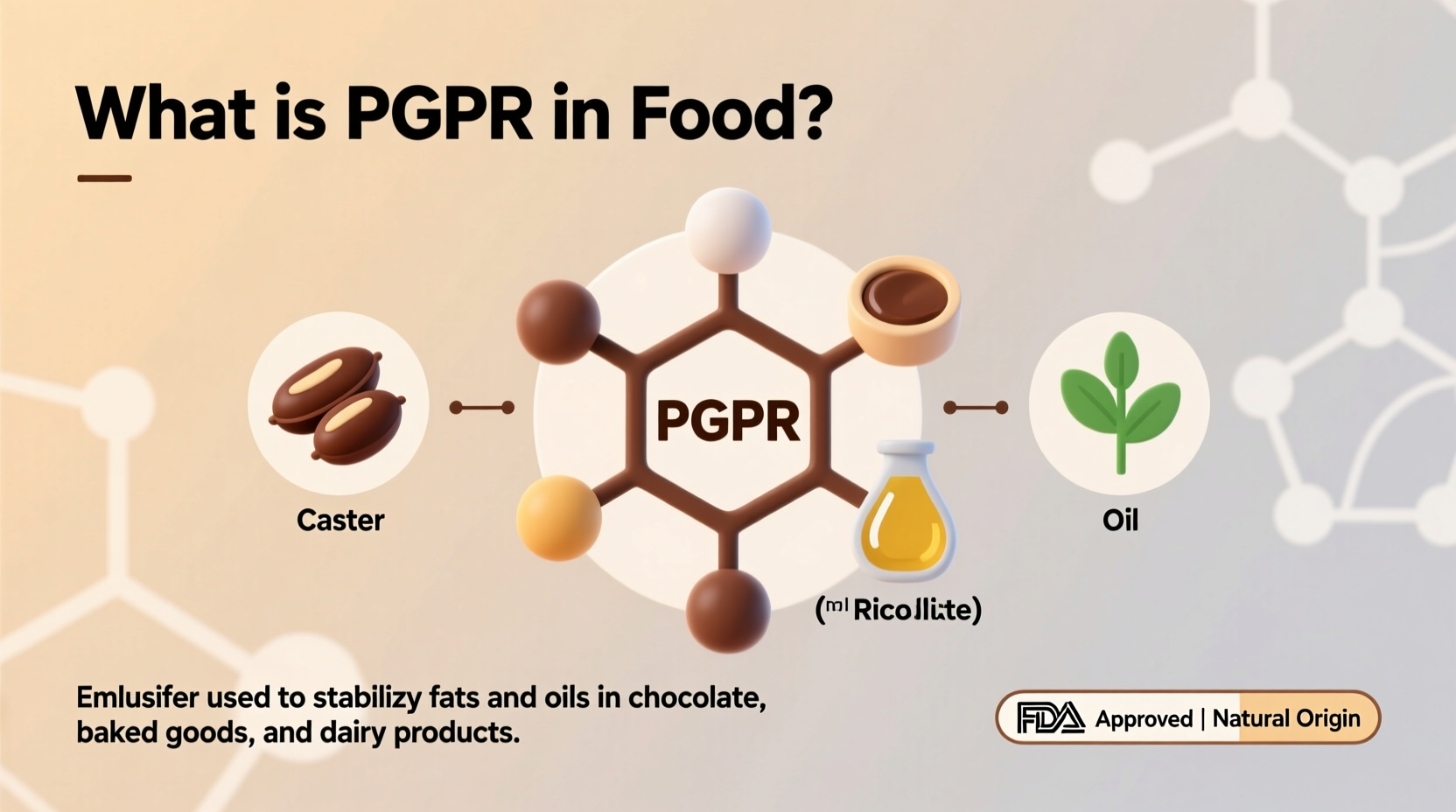

PGPR, or Polyglycerol Polyricinoleate, serves as a crucial emulsifier in food manufacturing, particularly within chocolate and confectionery products. This plant-based additive, coded as E476 in Europe, functions by reducing surface tension between cocoa particles and fat components. Derived from castor beans through a process of glycerolysis, PGPR creates more stable mixtures that maintain consistent texture throughout production and shelf life.

When added to chocolate formulations at concentrations between 0.1% and 0.5%, PGPR significantly improves flow properties during manufacturing. This technical advantage allows chocolate producers to reduce cocoa butter content by up to 10% while maintaining the same mouthfeel and appearance—making it both a functional and economic solution for food manufacturers worldwide.

How PGPR Works in Chocolate Manufacturing

The magic of PGPR happens at the molecular level. When incorporated into chocolate mixtures, its unique chemical structure allows it to position itself between cocoa particles and fat molecules. This positioning creates a lubricating effect that reduces friction during processing. The practical result? Chocolate that flows more easily through production equipment, fills molds more completely, and creates smoother finished products.

Without emulsifiers like PGPR, chocolate manufacturers would need to increase cocoa butter content substantially to achieve similar flow characteristics—driving up production costs significantly. This explains why PGPR has become standard in many commercial chocolate products, from candy bars to baking chocolate.

| Food Product | Typical PGPR Concentration | Primary Function |

|---|---|---|

| Dark Chocolate | 0.10-0.25% | Improves flow, reduces cocoa butter needed |

| Milk Chocolate | 0.15-0.30% | Prevents sugar crystallization |

| Chocolate Coatings | 0.20-0.40% | Ensures even coverage on confections |

| Cocoa Powder Mixes | 0.05-0.15% | Improves dispersion in liquids |

Regulatory Approval and Safety Assessment Timeline

PGPR's journey from laboratory discovery to food industry staple followed a rigorous scientific evaluation process. Understanding this timeline helps contextualize current safety assessments:

- 1960s: Initial development of PGPR for industrial applications

- 1972: First approved for food use in Europe (E476)

- 1983: FDA grants Generally Recognized As Safe (GRAS) status

- 2000s: Comprehensive re-evaluations by EFSA and JECFA

- 2017: EFSA establishes acceptable daily intake of 7.5 mg/kg body weight

- 2022: Joint FAO/WHO committee confirms safety at current usage levels

This progressive evaluation demonstrates how food safety authorities continuously monitor additives as scientific understanding advances. Each reassessment incorporated newer research methodologies and more sophisticated analytical techniques.

Where You'll Find PGPR in Your Food

While chocolate represents PGPR's primary application, this versatile emulsifier appears in several food categories. Knowing where to look helps consumers make informed choices based on their personal preferences:

Chocolate products constitute approximately 95% of PGPR usage in food manufacturing. You'll most commonly encounter it in commercial chocolate bars, baking chocolate, chocolate coatings for ice cream and candies, and ready-to-use baking mixes. The additive proves particularly valuable in products requiring thin, even coatings that maintain structural integrity at room temperature.

PGPR remains absent from premium artisanal chocolates, organic-certified chocolate products (in most regions), and products specifically labeled "no emulsifiers." It's also not used in non-chocolate applications like baked goods, dairy products, or savory foods—its functionality being specific to cocoa-based formulations.

Safety Profile and Consumption Guidelines

Multiple global food safety authorities have evaluated PGPR through decades of research. The European Food Safety Authority (EFSA) established an acceptable daily intake (ADI) of 7.5 mg per kilogram of body weight, while the FDA maintains its GRAS (Generally Recognized As Safe) designation. These assessments considered potential impacts on digestion, metabolism, and long-term health.

For a 150-pound adult, this translates to approximately 500 mg of PGPR daily—the equivalent of consuming more than 2 pounds of standard chocolate products containing the maximum permitted concentration. Actual consumption typically remains well below these thresholds, with average daily intake estimated at less than 10% of the ADI.

Unlike some emulsifiers that have raised digestive concerns in recent research, PGPR shows minimal interaction with gut microbiota according to 2021 studies published in the Journal of Food Science. Its large molecular structure prevents significant absorption in the digestive tract, with most passing through the system unchanged.

Making Informed Choices About PGPR

Understanding PGPR empowers consumers to navigate food choices aligned with their personal preferences. Those seeking to avoid emulsifiers can identify products labeled "single-origin chocolate" or "crafted with cocoa butter only," which typically omit additives like PGPR. Reading ingredient lists for "E476" or "polyglycerol polyricinoleate" provides definitive identification.

For most consumers, PGPR presents no health concerns at typical consumption levels. However, individuals with specific dietary restrictions or those following strict whole-food diets might prefer products without emulsifiers. The key is recognizing that PGPR serves a technical function in manufacturing rather than providing nutritional value—helping create consistent, high-quality chocolate products at accessible price points.

Future Developments in Chocolate Emulsification

Food scientists continue researching alternatives to traditional emulsifiers like PGPR. Current investigations focus on enzymatic modification of cocoa components to achieve similar flow properties without additives. Some premium chocolate manufacturers have developed proprietary processes using optimized cocoa butter crystallization instead of emulsifiers.

However, PGPR remains the industry standard for commercial chocolate production due to its effectiveness, safety profile, and cost efficiency. As consumer preferences evolve, we may see more "clean label" chocolate options emerging, though complete elimination of emulsifiers would likely increase production costs substantially.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4