Listeria monocytogenes poses unique food safety challenges because it thrives in refrigerated environments where other bacteria can't survive. Understanding contamination pathways helps protect vulnerable populations like pregnant women, elderly individuals, and immunocompromised people from severe listeriosis infections.

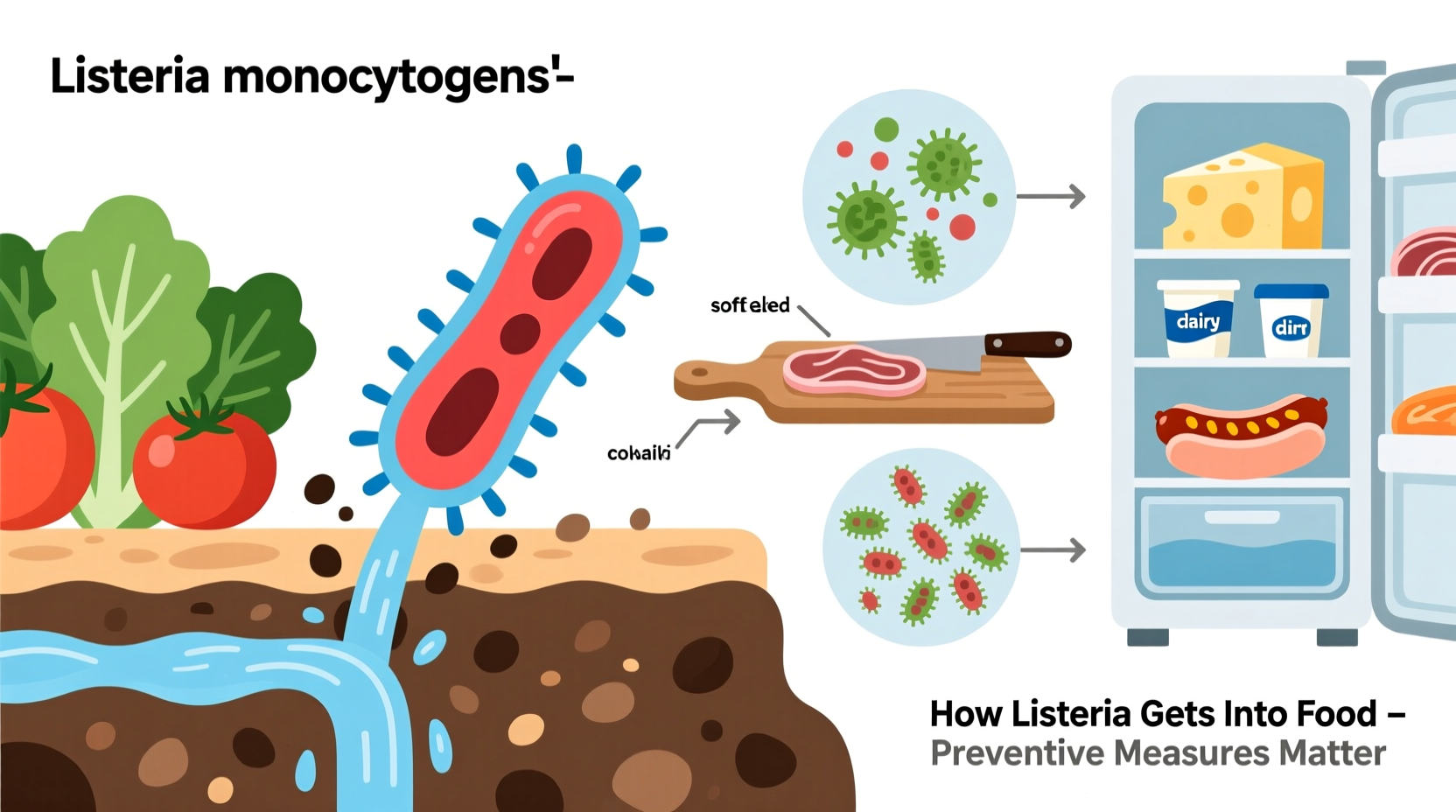

How Listeria Naturally Enters the Food Chain

Listeria bacteria exist naturally in soil and water, creating unavoidable exposure risks for agricultural products. When rain or irrigation water carries Listeria monocytogenes from contaminated soil onto crops, the bacteria can adhere to plant surfaces through specialized attachment proteins. Unlike many pathogens, Listeria forms protective biofilms that help it withstand environmental stressors.

According to the Centers for Disease Control and Prevention (CDC), approximately 1,600 Americans contract listeriosis annually, with 260 fatalities. This highlights why understanding contamination routes is critical for prevention.

Primary Contamination Pathways in Food Production

Modern food production systems introduce multiple opportunities for Listeria introduction. The bacteria's ability to persist in processing environments makes it particularly challenging to eliminate once established.

| Contamination Source | Transmission Mechanism | Prevention Strategy |

|---|---|---|

| Soil and Water | Natural presence in environment contaminates produce during growth | Proper field sanitation, water testing, post-harvest washing |

| Animal Carriers | Asymptomatic animals spread bacteria through feces | Manure management, livestock testing, separation protocols |

| Processing Facilities | Persistent biofilms in drains, equipment, and surfaces | Environmental monitoring, sanitation validation, equipment design |

| Cross-Contamination | Transfer from raw to ready-to-eat foods via surfaces or utensils | Dedicated equipment, strict zoning, employee hygiene protocols |

The Listeria Survival Timeline in Food Facilities

Unlike most foodborne pathogens, Listeria establishes persistent contamination through a predictable progression:

- Initial Introduction (Day 1): Enters facility via raw materials, equipment, or personnel

- Surface Attachment (Days 2-7): Forms initial biofilm on moist surfaces like drains and conveyor belts

- Biofilm Maturation (Weeks 2-4): Develops complex protective matrix resistant to standard cleaning

- Product Contamination (Ongoing): Transfers to food through direct contact or aerosolized particles

- Environmental Persistence (Months+): Survives in facility despite routine sanitation efforts

The FDA's Listeria guidance document confirms that once established in a facility, Listeria can persist for years, causing recurring contamination events. This explains why some food recalls happen repeatedly from the same manufacturer.

High-Risk Foods and Vulnerable Populations

Certain foods present elevated Listeria risks due to production methods or consumption patterns:

- Ready-to-eat meats: Deli counters account for 33% of listeriosis cases according to CDC data

- Unpasteurized dairy products: Raw milk is 150 times more likely to cause illness than pasteurized products

- Pre-cut fruits and vegetables: Increased surface area and handling opportunities

- Refrigerated pâtés and meat spreads: Long storage periods at ideal bacterial growth temperatures

Pregnant women face 10 times higher risk of listeriosis, with potential for miscarriage or stillbirth. The elderly (65+) account for 60% of Listeria-related deaths despite representing only 15% of cases.

Practical Prevention Strategies for Consumers

While food manufacturers bear primary responsibility for prevention, consumers can reduce risk through these evidence-based practices:

Refrigeration Management

Maintain refrigerator temperature at 40°F (4°C) or below—Listeria growth slows significantly below this threshold. Use a refrigerator thermometer for accuracy, as built-in dials are often unreliable. Consume opened ready-to-eat foods within 3-5 days.

Cross-Contamination Prevention

Designate specific cutting boards for produce versus meats. Wash all utensils and surfaces with hot, soapy water after contact with raw foods. The USDA recommends using a bleach solution (1 tablespoon per gallon of water) for sanitizing food-contact surfaces.

High-Risk Food Handling

Reheat deli meats to steaming hot (165°F) before consumption. Avoid unpasteurized dairy products entirely if pregnant or immunocompromised. Rinse all produce thoroughly under running water—even items with inedible rinds like cantaloupe.

Industry Prevention Measures That Work

Food manufacturers implement multiple safeguards to prevent Listeria contamination:

- Environmental monitoring programs: Regular testing of food contact surfaces

- Validated sanitation procedures: Using appropriate chemicals and contact times

- Product reformulation: Adjusting pH or water activity to inhibit growth

- Post-packaging pasteurization: For certain ready-to-eat products

The Food Safety Modernization Act (FSMA) requires facilities to implement preventive controls specifically for environmental pathogens like Listeria. Companies that follow the FDA's Listeria Control Guidance have demonstrated significant reductions in contamination incidents.

When Listeria Prevention Fails: Recognizing Symptoms

Listeriosis symptoms typically appear 1-4 weeks after exposure but can take up to 70 days. Mild cases present with fever, muscle aches, and gastrointestinal symptoms. Severe cases involve headache, stiff neck, confusion, loss of balance, or convulsions.

High-risk individuals should seek medical attention immediately if experiencing symptoms after consuming potentially contaminated foods. Early antibiotic treatment significantly improves outcomes for invasive listeriosis.

Emerging Prevention Technologies

Food safety researchers are developing innovative approaches to combat Listeria:

- Bacteriophage treatments: Targeted viruses that destroy Listeria without affecting other bacteria

- Advanced sanitation robotics: Automated systems that reach difficult-to-clean areas

- Real-time monitoring sensors: Detecting bacterial presence before contamination spreads

- Natural antimicrobial compounds: Plant-derived substances that inhibit Listeria growth

These technologies show promise but require further validation before widespread implementation. Current prevention still relies primarily on established sanitation and handling practices.

Common Misconceptions About Listeria

Several persistent myths undermine effective prevention:

- "Refrigeration kills Listeria" - False: It grows at refrigerator temperatures

- "Cooking destroys all Listeria risk" - Only true if proper internal temperatures are reached

- "Organic foods are safer" - No evidence that organic production reduces Listeria risk

- "Only deli meats are problematic" - Multiple food categories have caused outbreaks

Understanding these misconceptions helps consumers make informed decisions about food safety practices.

Key Takeaways for Food Safety

Preventing Listeria contamination requires vigilance at every stage of the food chain. Consumers should prioritize proper refrigeration, avoid high-risk foods when vulnerable, and practice strict cross-contamination prevention. Food manufacturers must implement comprehensive environmental monitoring and sanitation validation programs.

By understanding how Listeria enters food and persists in environments, we can significantly reduce the risk of this serious foodborne illness. Staying informed about food recalls and following evidence-based safety practices provides the best protection against listeriosis.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4