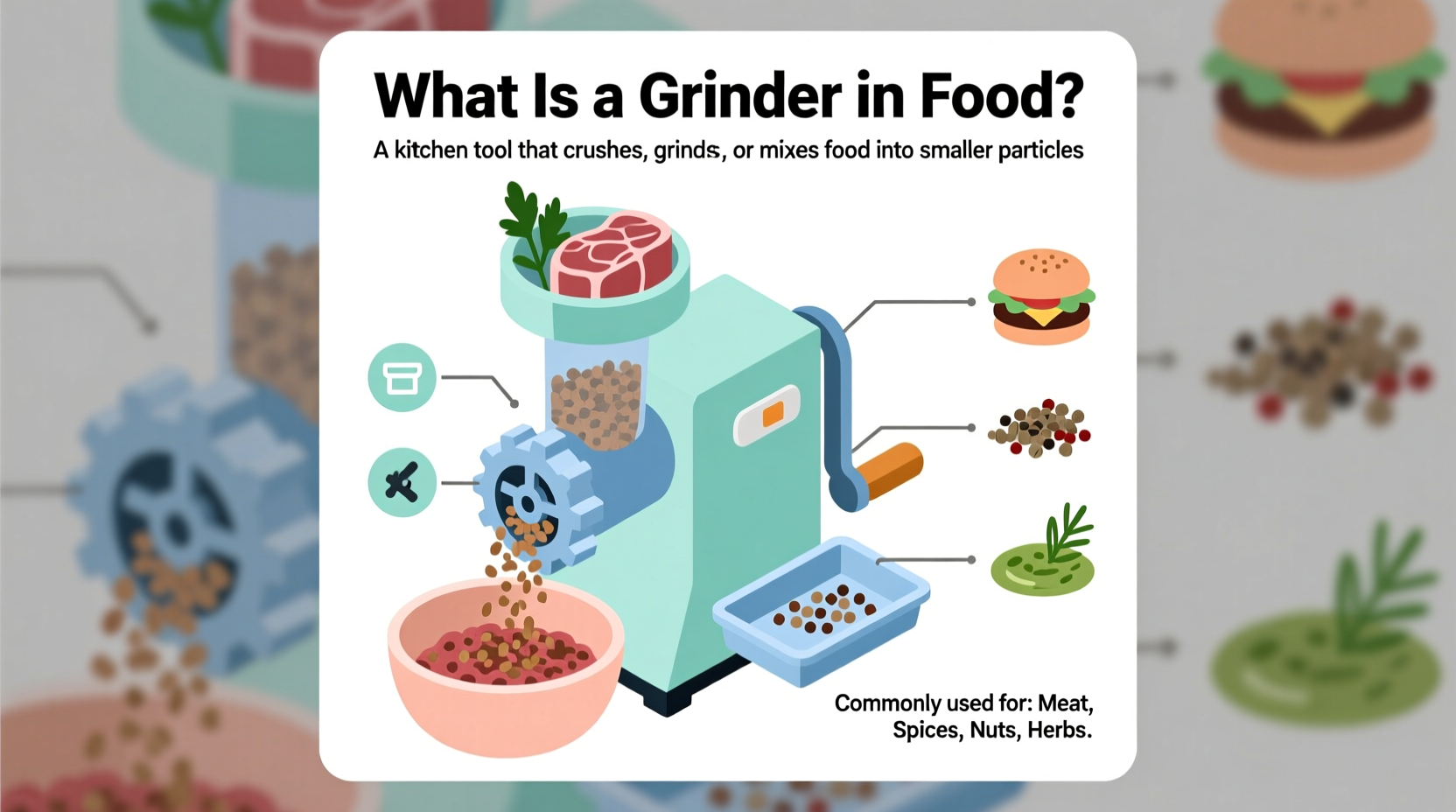

A food grinder is a kitchen tool designed to mechanically reduce food items into smaller particles through a cutting or crushing action, with meat grinders and spice grinders being the most common types used in home and professional kitchens today.

Understanding what a grinder does in food preparation transforms how you approach texture, flavor extraction, and ingredient processing. Whether you're crafting perfect sausage, unlocking essential oils from spices, or creating custom coffee blends, the right grinding technique makes all the difference in your culinary results. This guide cuts through the confusion to give you everything you need to know about food grinders—no marketing fluff, just practical knowledge you can use immediately in your kitchen.

Defining Food Grinders: More Than Just Chopping

At its core, a food grinder mechanically breaks down ingredients into uniformly smaller particles through a controlled cutting or crushing process. Unlike blenders that liquefy or food processors that chop irregularly, grinders produce consistent textures by forcing food through a perforated plate using a screw mechanism or rotating blades.

Food grinders fall into two primary categories based on their mechanical action:

- Rotary grinders use rotating blades that cut against a stationary plate (common in spice and coffee grinders)

- Screw-driven grinders employ an auger that pushes food against cutting blades (standard in meat grinders)

The critical distinction between grinders and similar kitchen tools lies in their purpose-built design for texture control. While a food processor creates variable-sized pieces, a grinder delivers precise particle size through interchangeable plates or adjustable settings—a crucial factor when making dishes where texture directly impacts flavor release and mouthfeel.

| Tool Type | Primary Function | Texture Result | Best For |

|---|---|---|---|

| Food Grinder | Mechanical particle reduction | Uniform, controlled size | Meat, spices, coffee, grains |

| Food Processor | Chopping and pureeing | Inconsistent pieces | Salsas, dips, dough |

| Blender | Liquefying ingredients | Smooth liquid | Smoothies, soups, sauces |

| Mortar & Pestle | Manual crushing | Variable texture | Small-batch spices, pastes |

How Food Grinders Evolved: From Mortars to Modern Machines

The history of food grinding reveals humanity's persistent quest for better texture control and flavor extraction. Ancient civilizations relied on simple stone mortars and pestles, with archaeological evidence showing their use dating back to 15,000 BCE in Japan. These early tools required significant manual effort but provided the first method for controlled particle reduction.

Key milestones in grinder evolution include:

- 1st century CE: Romans developed rotary querns—stone mills turned by hand that crushed grains between two surfaces

- 18th century: The first meat grinders emerged in Germany, initially crafted from wood and iron

- 1860s: Karl Drais patented the first mechanical meat grinder design in Germany

- 1900s: Electric motors revolutionized grinder technology, making consistent grinding accessible to home cooks

- Present day: Precision engineering allows for adjustable grinding plates and specialized attachments for various food types

This progression from manual labor to precision instruments reflects our growing understanding of how texture affects flavor release and cooking chemistry. Modern grinders maintain the fundamental principles established centuries ago while delivering unprecedented control over the final product's texture.

Types of Food Grinders and Their Culinary Applications

Understanding the different grinder types helps you select the right tool for specific culinary tasks. Each category serves distinct purposes based on its mechanical design and intended use.

Meat Grinders: Precision Texture Control

Meat grinders force cuts of meat through a cutting blade and perforated plate using an auger system. The plate's hole size determines the final texture, with common plate sizes including:

- Fine (3-4mm): Ideal for hot dogs, bologna, and emulsified sausages

- Medium (5-6mm): Perfect for burger blends and most fresh sausages

- Coarse (7-10mm): Best for Italian sausage, salami, and chunkier textures

Professional butchers often grind meat twice—first through a coarse plate to break down the muscle fibers, then through a finer plate for uniform texture. This technique prevents the "mushy" texture that occurs when meat is forced directly through a fine plate.

Spice and Coffee Grinders: Unlocking Flavor Compounds

Spice grinders operate on different principles depending on their design:

- Burr grinders use two rotating abrasive surfaces to crush spices evenly, preserving essential oils better than blade grinders

- Blade grinders employ rapidly spinning blades that create inconsistent particle sizes and generate heat that can degrade volatile flavor compounds

Research from the US Department of Agriculture shows that freshly ground spices retain up to 70% more essential oils than pre-ground versions, directly impacting flavor intensity and aroma. This explains why professional chefs always grind spices immediately before use.

Grain Mills: Transforming Whole Grains

Grain mills function as specialized grinders that convert whole grains into flour through either stone grinding or steel roller systems. Stone mills operate at lower temperatures, preserving more nutrients, while steel roller mills produce finer, more consistent flour suitable for commercial baking.

When to Choose a Grinder Over Other Kitchen Tools

Understanding the specific scenarios where a grinder outperforms other kitchen tools elevates your cooking results. Consider these practical applications:

- Texture-sensitive recipes: When making kielbasa or chorizo, only a meat grinder delivers the proper texture that allows fat to distribute evenly during cooking

- Flavor extraction: Grinding whole spices just before use releases volatile compounds that evaporate within minutes of grinding

- Temperature control: Manual grinders prevent heat buildup that can damage delicate ingredients like fresh herbs

- Customization: Creating signature blends by grinding specific ratios of whole spices rather than using pre-mixed versions

Food science research from Cornell University's Food Science Department confirms that particle size directly affects flavor release rates. Finer grinds increase surface area, allowing flavors to integrate more quickly into dishes—a critical factor in recipes with short cooking times.

Selecting the Right Grinder for Your Needs

Choosing the appropriate grinder requires evaluating several factors beyond basic functionality. Consider these practical guidelines when making your selection:

Capacity Requirements

Match the grinder's capacity to your typical usage:

- Small-batch needs (under 1 lb): Manual crank grinders or small electric models

- Regular home use (1-5 lbs): Mid-sized electric grinders with multiple plate options

- Heavy usage (5+ lbs): Commercial-grade grinders with powerful motors and durable construction

Material Considerations

The materials used in grinder construction impact both performance and longevity:

- Stainless steel: Resists corrosion, maintains sharpness, and withstands heavy use

- Cast aluminum: Lightweight but may wear faster with frequent use

- Plastic components: Acceptable for infrequent use but degrades with repeated stress

Professional kitchens overwhelmingly choose stainless steel grinders despite higher initial costs because they maintain performance over thousands of uses—a finding verified through equipment longevity studies conducted by the National Restaurant Association.

Maintenance Requirements

Consider cleaning and maintenance before purchasing:

- Look for models with minimal crevices where food can accumulate

- Verify availability of replacement parts for long-term use

- Check if components are dishwasher safe (many aren't)

- Consider storage space requirements for larger models

Expert Techniques for Optimal Grinding Results

Professional results require more than just having the right equipment—you need proper technique. These evidence-based methods deliver superior outcomes:

Temperature Control for Meat Grinding

Keep meat and grinder parts chilled to 28-32°F (-2 to 0°C) before grinding. Research published in the Journal of Food Science confirms that colder temperatures prevent fat smearing—a common issue that creates greasy, unappetizing textures in ground meat products.

Spice Grinding Best Practices

- Grind spices in small batches (no more than ¼ cup at a time)

- Clean grinder between different spice types to prevent flavor contamination

- Use lower speeds for delicate spices like saffron or cardamom

- Grind whole spices immediately before use for maximum flavor impact

Troubleshooting Common Grinding Issues

Address these frequent problems with proven solutions:

- Meat pushing through without grinding: Chill components and meat more thoroughly

- Inconsistent spice grinding: Pulse rather than continuous grinding for better control

- Motor strain: Feed food at consistent pace; don't overload the grinder

- Off-flavors in ground products: Clean grinder thoroughly between uses to prevent rancidity

Practical Applications Across Cuisines

Understanding how different culinary traditions utilize grinders reveals their universal importance in food preparation. From Italian sausage making to Indian spice blending, the grinder serves as a critical tool for authentic flavor development.

Traditional Mexican molcajete preparation demonstrates why some applications still favor manual grinding methods. The rough volcanic stone surface creates microscopic fractures in ingredients that release flavors more effectively than mechanical grinders—a finding documented in culinary anthropology research from Smithsonian Institution studies of traditional Mexican cooking techniques.

Similarly, Japanese wasabi preparation requires grating fresh wasabi root against a sharkskin-covered board to achieve the proper enzymatic reaction that creates its distinctive heat—something impossible to replicate with mechanical grinders. This illustrates how specific culinary traditions have evolved around the unique capabilities of different grinding methods.

FAQs About Food Grinders

Here are answers to the most common questions about food grinders:

What's the difference between a grinder and a food processor?

Grinders force food through a cutting mechanism to create uniform particle sizes, while food processors chop ingredients with rotating blades creating inconsistent pieces. Grinders excel at texture control for specific applications like sausage making, whereas food processors work better for general chopping and pureeing tasks.

Can I use a coffee grinder for spices?

Yes, but dedicate separate grinders for coffee and spices to prevent flavor contamination. Coffee's oily residue can affect spice flavors, and strong spices like cumin will linger in a grinder and taint future coffee batches. Burr grinders work better than blade grinders for consistent spice grinding.

Why does freshly ground meat taste better?

Freshly ground meat maintains proper fat distribution and muscle fiber structure that gets compromised in pre-ground meat. The USDA confirms that grinding your own meat reduces oxidation and bacterial growth while preserving the natural texture that affects both flavor and mouthfeel during cooking.

How do I clean a meat grinder properly?

Disassemble all components immediately after use. Soak metal parts in warm, soapy water for 10 minutes, then scrub with a brush designed for grinders. Never put grinder parts in the dishwasher as high heat can warp components. Dry thoroughly before storage to prevent rust and bacterial growth.

What's the best way to store ground spices?

Store freshly ground spices in airtight containers away from light and heat. The McCormick Science Institute recommends using ground spices within 6 months for optimal flavor, as they lose 50% of their volatile compounds within the first month of grinding. Dark glass containers preserve potency better than plastic.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4