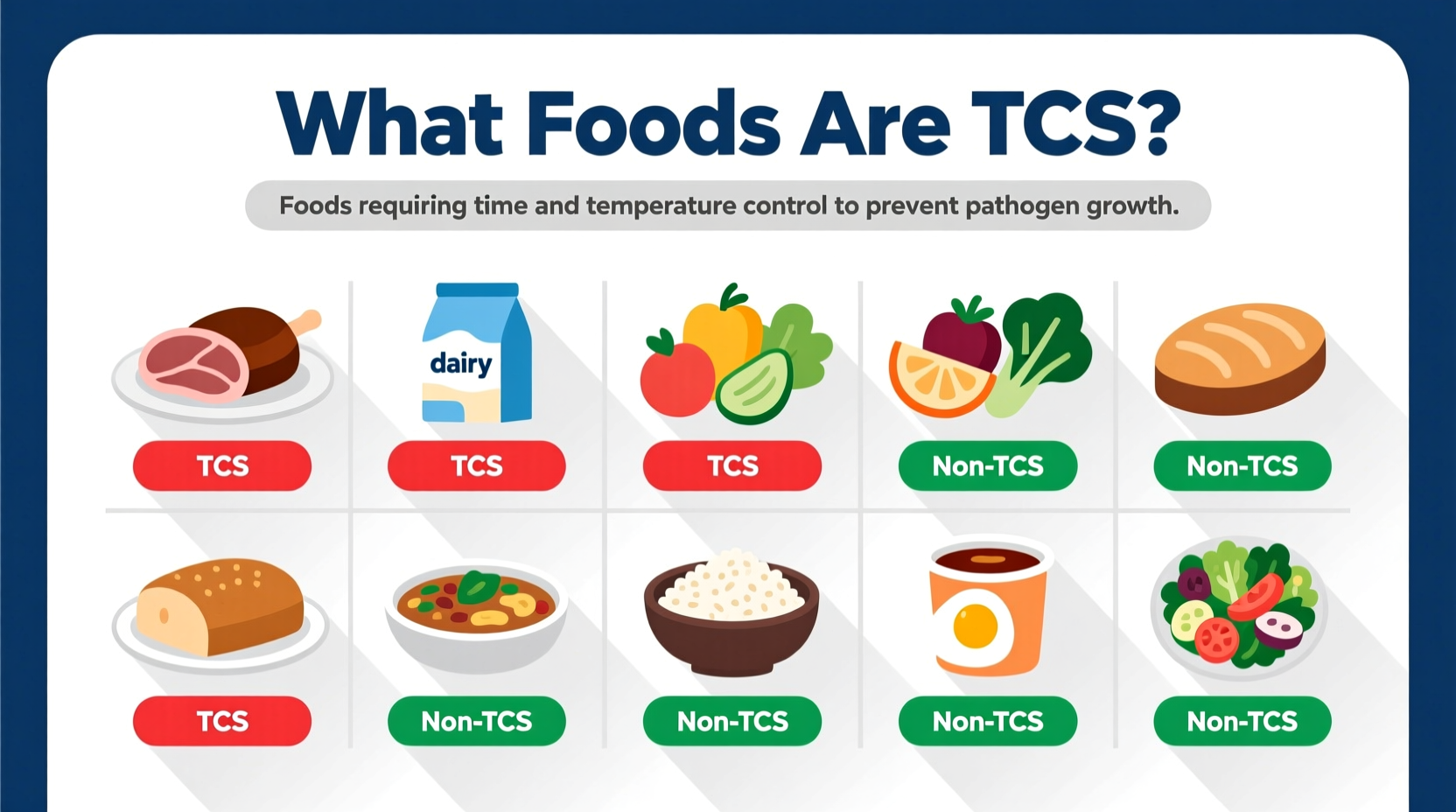

TCS foods (Time/Temperature Control for Safety foods) are specific food items requiring proper temperature management to prevent dangerous pathogen growth. The FDA Food Code identifies these high-risk foods that must be kept out of the temperature danger zone (40°F-140°F) to ensure public safety in food service environments.

Why Understanding TCS Foods Matters for Food Safety

Every year, foodborne illnesses affect millions of people globally. Proper identification and handling of TCS foods forms the cornerstone of food safety protocols in restaurants, schools, hospitals, and other food service operations. When you correctly manage these high-risk foods, you significantly reduce the chance of outbreaks that could harm customers and damage your business reputation.

What Exactly Are TCS Foods?

TCS stands for Time/Temperature Control for Safety. These foods require specific temperature management because they create ideal conditions for harmful bacteria like Salmonella, E. coli, and Listeria to multiply rapidly. The FDA Food Code defines TCS foods as those requiring time and temperature controls because they:

- Have a pH between 4.6 and 7.5

- Contain protein

- Have moderate to high moisture content

- Are capable of supporting pathogen growth

Complete List of TCS Foods by Category

Understanding which foods fall under TCS classification helps food handlers implement proper safety measures. The following table organizes TCS foods by category for quick reference:

| Food Category | Specific TCS Foods | Special Handling Considerations |

|---|---|---|

| Dairy Products | Milk, cheese (soft/unripened), yogurt, custard | Keep below 40°F; avoid cross-contamination |

| Meat & Poultry | Beef, pork, lamb, chicken, turkey | Cook to proper internal temperatures; separate raw from ready-to-eat |

| Fish & Shellfish | Fresh fish, shellfish, sushi-grade fish | Store at 38°F or below; monitor for freshness |

| Eggs | Raw shell eggs, liquid eggs, egg dishes | Cook to 160°F; avoid room temperature storage |

| Cooked Starches | Cooked rice, pasta, potatoes, beans | Cool rapidly; don't leave at room temperature |

| Cut Produce | Sliced melons, cut tomatoes, leafy greens | Store below 41°F; use within 7 days |

| Plant-based Proteins | Tofu, tempeh, seitan | Follow same protocols as animal proteins |

Key Factors That Make Foods TCS

Understanding why certain foods qualify as TCS helps food handlers make informed decisions beyond just memorizing lists. Four critical factors determine TCS classification:

pH Level Analysis

Foods with a pH between 4.6 and 7.5 provide the neutral environment pathogens need to thrive. Highly acidic foods (pH below 4.6) like vinegar or citrus generally don't support dangerous bacterial growth. The FDA's Food Code specifies that foods within this pH range require temperature control.

Water Activity (aw)

Water activity measures available moisture in food. TCS foods typically have water activity above 0.85, providing sufficient moisture for microbial growth. Foods like dried spices or crackers with low water activity don't require the same temperature controls.

Temperature Danger Zone Timeline

When TCS foods remain in the temperature danger zone (40°F-140°F), pathogens can double every 20 minutes. The FDA Food Code specifies that TCS foods shouldn't remain in this zone for more than 4 hours cumulatively during preparation, storage, and service. This timeline explains why rapid cooling and proper holding temperatures are critical.

Protein Content Assessment

Foods rich in protein provide essential nutrients for bacterial growth. This explains why meat, dairy, eggs, and certain plant proteins fall under TCS classification while simple carbohydrates like sugar don't.

Practical TCS Food Handling Guidelines

Knowing which foods are TCS matters little without proper handling procedures. Implement these evidence-based practices:

Temperature Monitoring Protocol

Use calibrated thermometers to verify temperatures at critical points. The FDA Food Code requires:

- Refrigeration below 40°F (ideally 38°F)

- Hot holding above 140°F

- Cooking to minimum internal temperatures (e.g., poultry 165°F)

Cooling Procedures That Work

Rapid cooling prevents pathogen growth during the critical transition from cooking to storage. Follow the FDA's two-stage cooling method:

- Cool from 135°F to 70°F within 2 hours

- Cool from 70°F to 40°F within additional 4 hours

Cross-Contamination Prevention

Use separate cutting boards, utensils, and storage containers for raw and ready-to-eat TCS foods. The CDC identifies cross-contamination as a leading cause of foodborne illness outbreaks in commercial kitchens.

Common TCS Food Mistakes to Avoid

Even experienced food handlers sometimes make critical errors with TCS foods:

- Assuming all cheeses are safe at room temperature - Soft cheeses like feta and brie require refrigeration

- Misjudging cooling times - Large containers of soup or stew cool too slowly in the center

- Ignoring cut produce risks - Sliced watermelon becomes a TCS food requiring temperature control

- Overlooking plant-based proteins - Tofu and tempeh require the same handling as animal proteins

When TCS Classification Changes: Special Cases

Some foods become TCS only after specific preparation steps:

- Whole melons aren't TCS, but sliced melons are

- Whole tomatoes aren't TCS, but cut tomatoes are

- Dry rice isn't TCS, but cooked rice is

This transformation occurs because preparation increases moisture availability and surface area, creating conditions favorable for pathogen growth. The FDA's Food Code specifically addresses these special cases to prevent confusion during health inspections.

Resources for Continued Learning

Stay updated with the latest food safety guidelines through these authoritative sources:

- FDA Food Code 2022 - Official guidelines for food service

- CDC Food Safety Resources - Current outbreak information and prevention strategies

- USDA Food Safety and Inspection Service - Meat, poultry, and egg product regulations

Implementing TCS Knowledge in Your Food Operation

Understanding what foods are TCS represents just the first step. Create actionable protocols by:

- Conducting a TCS food inventory in your establishment

- Developing specific temperature monitoring schedules

- Training staff on proper handling procedures for each TCS category

- Implementing verification procedures to ensure compliance

Regularly review and update your food safety plan to incorporate the latest research and regulatory requirements. Remember that proper TCS food handling isn't just about passing inspections—it's about protecting your customers and your business reputation.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4