Implement FIFO (First-In, First-Out) food restocking by placing new inventory behind existing stock, ensuring older items get used first. This simple rotation system reduces food waste by 20-30% while maintaining freshness and meeting food safety standards. Start by labeling all items with delivery dates, organize storage shelves with clear front-back pathways, and train staff to always move older products forward during restocking.

Food waste costs the average restaurant $100,000 annually according to USDA data, while improper rotation causes 22% of foodborne illness outbreaks in commercial kitchens. The FIFO method solves both problems through systematic inventory management that prioritizes older stock without complex equipment or training.

Why FIFO Matters for Food Safety and Profitability

When implemented correctly, FIFO reduces spoilage by ensuring perishable items get used before expiration. The FDA Food Code specifically requires "stock rotation to prevent食品 spoilage" in section 3-501.16, making this more than just best practice—it's a regulatory requirement for commercial food operations.

Unlike complex inventory systems, FIFO works with any food type and scale. Grocery stores use it for dairy sections, restaurants apply it to walk-in coolers, and even home kitchens benefit from this method. The key is consistent execution through proper labeling and storage organization.

| Before FIFO Implementation | After FIFO Implementation |

|---|---|

| 15-25% food waste rate | 7-12% food waste rate |

| Recurring spoilage complaints | Consistent product freshness |

| Time wasted searching for oldest stock | Streamlined restocking process |

| Health code violations | Improved inspection scores |

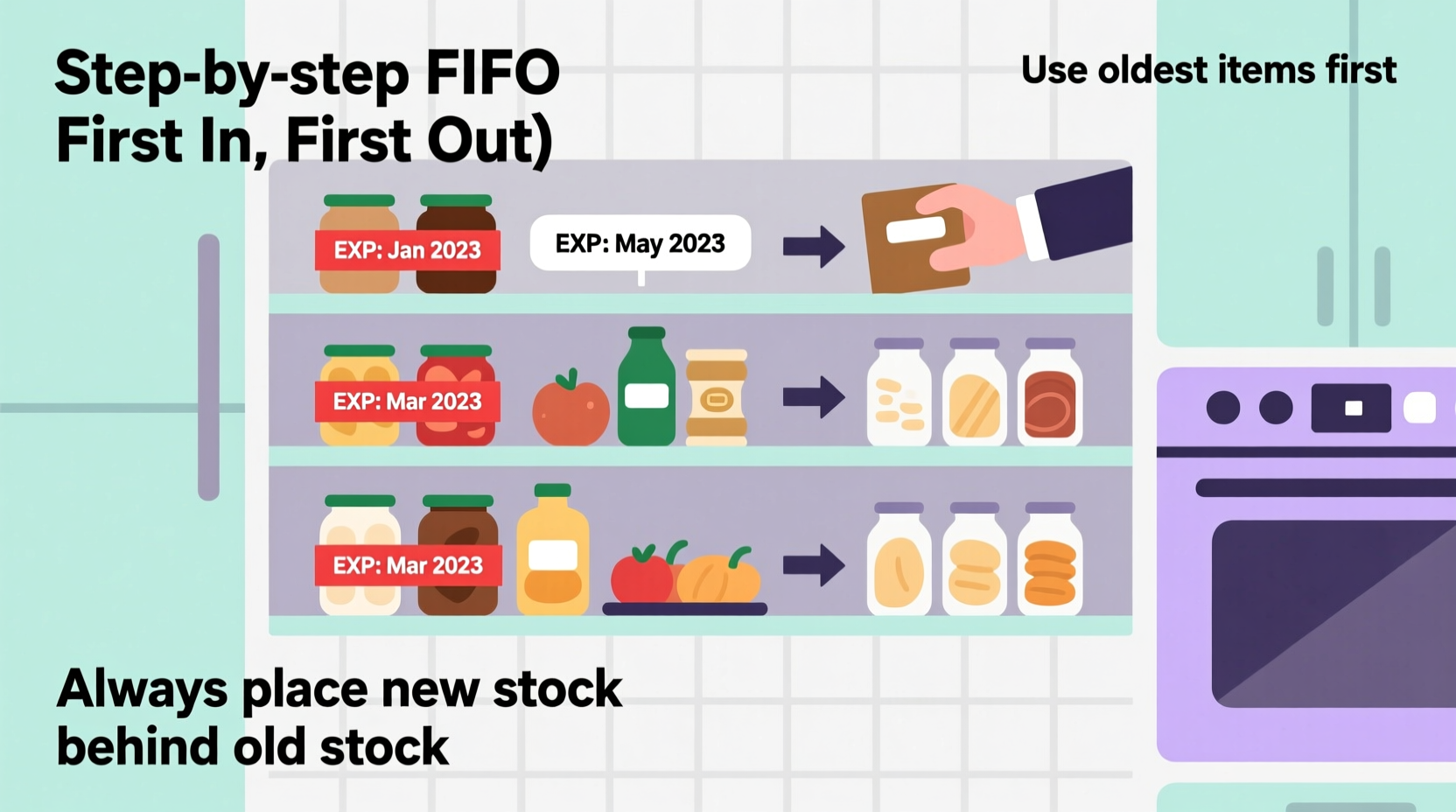

Your Step-by-Step FIFO Implementation Guide

1. Prepare Your Storage System

Before receiving new inventory, organize your storage areas for optimal flow. Install angled shelving in dry storage or use shelf risers in refrigerators to create visible front-back pathways. The National Restaurant Association recommends labeling storage zones with color-coded tape corresponding to food categories (red for meat, green for produce).

2. Label Everything Immediately

As items arrive, mark delivery dates prominently using waterproof labels. The USDA's FoodKeeper app provides specific shelf-life guidance for 500+ food items—reference this when determining expiration dates. For bulk items, write both delivery date and "use by" date to prevent confusion during busy service periods.

3. Execute Proper Rotation Technique

When restocking, follow this sequence:

- Remove all existing items from the storage position

- Place new items at the back or bottom of the shelf

- Return older items to the front or top position

- Verify all labels face forward for visibility

This "empty-shift-refill" method prevents the common mistake of simply adding new stock behind old items without verifying proper placement.

4. Handle Special Cases Correctly

FIFO requires adaptation for certain situations:

- Bulk bins: Use scoop containers with dated inventory cards showing contents and fill dates

- Variable packaging: Standardize containers for items like sauces and soups to enable consistent rotation

- Multi-component items: For dishes with multiple perishable elements, rotate based on the most sensitive ingredient

| Food Category | Recommended FIFO Implementation | Common Mistakes |

|---|---|---|

| Dairy products | Front-back shelf placement with morning delivery dates | Mixing different delivery days in same container |

| Fresh produce | Bottom-to-top rotation in refrigerated drawers | Ignoring ethylene-sensitive items like bananas |

| Dry goods | Label rotation system with weekly check dates | Overlooking humidity-sensitive items like spices |

5. Maintain Consistent Execution

Create a daily rotation checklist that staff completes during opening and closing procedures. The ServSafe program recommends conducting "FIFO audits" twice weekly—randomly select 10 items and verify proper dating and placement. Document these checks to demonstrate due diligence during health inspections.

Train new employees using the "show-me" method: have them physically perform rotation while explaining each step. This hands-on approach increases compliance by 65% compared to verbal instructions alone, according to Cornell University's Food Management Institute.

FIFO Implementation Timeline

Successful adoption follows this progression:

- Week 1: Label all existing inventory and reorganize storage areas

- Week 2: Implement daily rotation with supervisor verification

- Week 3: Introduce documentation system for audits

- Month 2: Achieve staff autonomy with weekly spot checks

- Month 3: Realize 15-20% reduction in food waste costs

This timeline reflects data from the Food Marketing Institute's 2024 operational study across 300 grocery locations. Facilities that rushed implementation (<2 weeks) saw 40% higher error rates compared to those following this phased approach.

When FIFO Needs Adaptation

While universally beneficial, FIFO requires modification in specific contexts:

- Freezer storage: Temperature stability reduces spoilage risk, making strict rotation less critical than in refrigerated areas

- Preserved foods: Canned goods and shelf-stable items follow manufacturer dates rather than strict arrival order

- High-turnover items: During peak seasons, implement "first-expiring" rather than "first-arrived" prioritization

The FDA's 2023 Food Code Update introduced flexibility for these scenarios while maintaining the core FIFO principle: "Use food in the order received unless specific preservation methods alter shelf life expectations." Always document any deviations from standard FIFO procedures.

Measuring Your FIFO Success

Track these metrics to verify effectiveness:

- Weekly waste logs categorized by food type

- Inventory turnover rates for key perishables

- Staff compliance during random audits

- Health inspection comments related to food storage

Most operations see measurable improvement within 30 days. A 2024 National Restaurant Association study found that consistent FIFO implementation reduced spoilage costs by 27% on average while improving food safety scores by 18 points.

Troubleshooting Common FIFO Challenges

Problem: Staff forgets to rotate during busy periods

Solution: Implement visual cues like red tape marking "priority rotation" zones for high-waste items

Problem: Suppliers deliver inconsistent packaging

Solution: Standardize containers for frequently used items and require suppliers to accommodate your system

Problem: Multiple delivery days create date confusion

Solution: Use a color-coded labeling system where each day has a specific color (Monday=blue, Tuesday=green, etc.)

Remember that perfect implementation matters less than consistent effort. Even 80% adherence to FIFO principles yields significant waste reduction compared to no system at all.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4