Understanding TCS Foods: Your Essential Food Safety Guide

When working with food, recognizing TCS items isn't just industry jargon—it's your first line of defense against foodborne illness. Whether you're a professional chef or home cook, understanding which foods require special temperature handling could prevent serious health risks.What Exactly Makes a Food "TCS"?

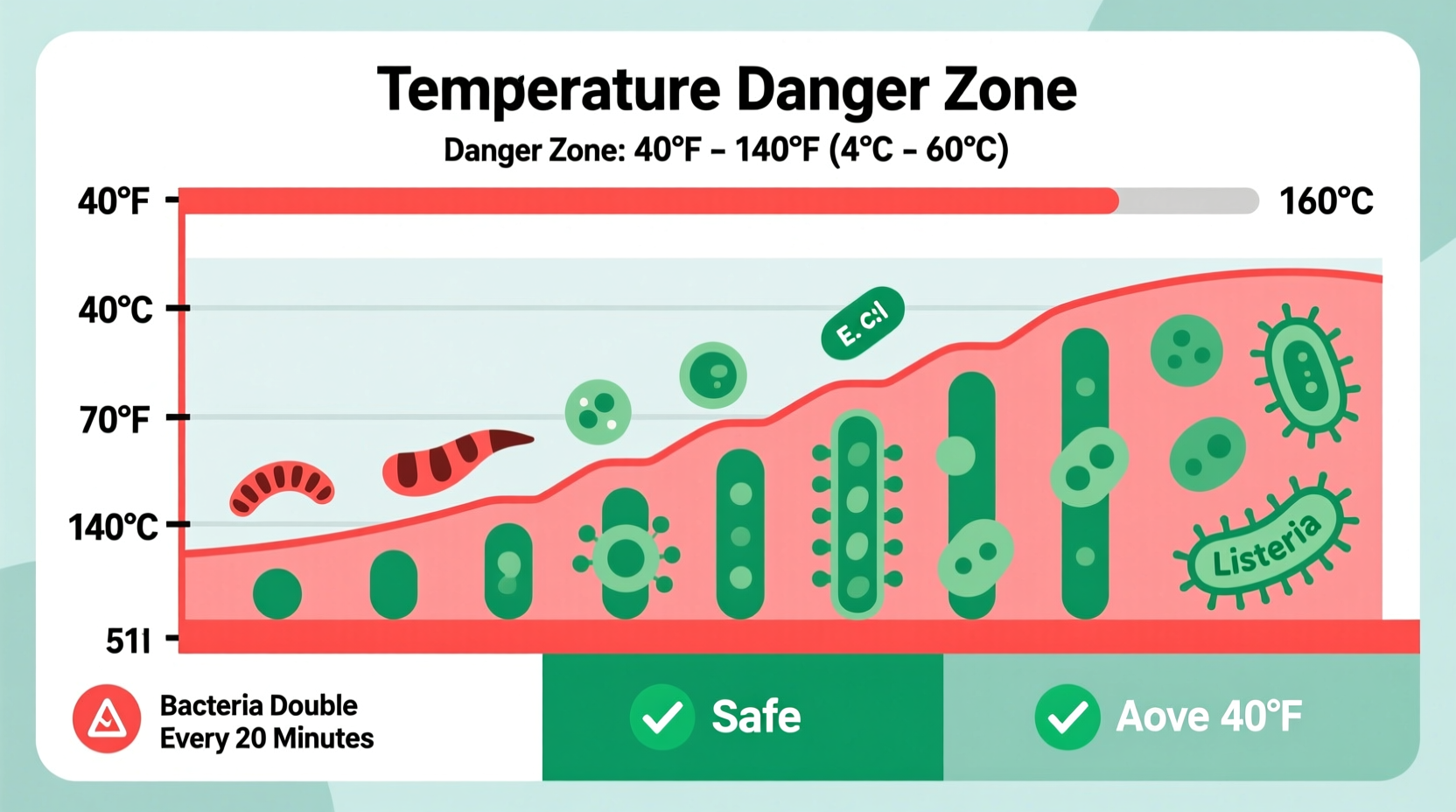

The FDA Food Code defines TCS foods as those requiring time and temperature controls to limit pathogen growth or toxin production. These foods typically share characteristics that create ideal conditions for bacteria like Salmonella, E. coli, and Listeria:

- High moisture content (water activity above 0.85)

- Near-neutral pH (4.6 or higher)

- Protein-rich composition

- Nutrient-dense properties

When these elements combine within the temperature danger zone (41°F-135°F/5°C-57°C), bacteria can double every 20 minutes. The FDA estimates improper TCS food handling contributes to nearly 40% of restaurant-related foodborne illness outbreaks.

Common TCS Food Categories You Need to Know

While the complete list appears in the FDA Food Code, these categories represent most foods requiring temperature control:

| TCS Food Category | Specific Examples | Special Handling Considerations |

|---|---|---|

| Dairy & Eggs | Milk, cheese (soft varieties), yogurt, custards, quiches | Soft cheeses like brie require stricter temperature control than aged cheeses |

| Meats & Proteins | Beef, poultry, fish, tofu, refried beans | Ground meats have greater surface area for bacterial growth |

| Cooked Plant Foods | Rice, pasta, potatoes, cooked vegetables | Cooked starches become increasingly dangerous as they cool |

| Ready-to-Eat Produce | Cut melons, tomatoes, leafy greens, garlic-in-oil | Cutting produces nutrients that accelerate bacterial growth |

The Temperature Danger Zone: A Timeline of Risk

Understanding how quickly bacteria multiply in TCS foods explains why temperature control is non-negotiable. The USDA Food Safety and Inspection Service documents this progression:

- 0-2 hours in danger zone: Generally safe, but monitoring required

- 2-4 hours: Bacterial levels reach concerning levels—consume immediately or discard

- 4+ hours: Pathogen levels become dangerously high—must discard

This timeline shortens significantly when temperatures approach 70°F (21°C), where bacteria grow most rapidly. The USDA confirms that at 90°F (32°C), some bacteria can double in just 10-20 minutes.

Practical Handling Guidelines for Different Settings

TCS food requirements adapt to various environments while maintaining core safety principles:

Commercial Kitchens

Follow the 2-hour/4-hour rule strictly. Install calibrated thermometers in all storage units and cooking equipment. Implement color-coded cutting boards for different food categories. The ServSafe program requires temperature logs for all TCS foods held for more than two hours.

Home Kitchens

Many home cooks don't realize that cooked rice or pasta left at room temperature becomes increasingly hazardous. Refrigerate leftovers within 2 hours (1 hour if room temperature exceeds 90°F). Use appliance thermometers to verify your refrigerator maintains 40°F or below.

Mobile & Temporary Operations

Food trucks and event vendors face unique challenges. The FDA requires insulated containers maintaining proper temperatures, with temperature verification every 4 hours. When power isn't available, use ice packs or thermal containers rated for 8+ hours of temperature maintenance.

Common Misconceptions About TCS Foods

Several persistent myths put people at risk:

- "If it smells fine, it's safe"—Many dangerous pathogens don't produce detectable odors

- "Refrigeration stops bacteria completely"—Some pathogens like Listeria grow slowly even at 34°F

- "All cheeses are TCS foods"—Aged cheeses with low moisture content (like parmesan) aren't considered TCS

- "Cooking destroys all toxins"—Some bacterial toxins (like those from Staphylococcus) remain dangerous after cooking

Essential TCS Food Safety Practices You Can Implement Today

Regardless of your kitchen setting, these evidence-based practices reduce risk:

- Temperature monitoring: Use calibrated thermometers—not guesswork—to verify storage and cooking temperatures

- Time management: Implement the 2-hour rule for foods left in the danger zone

- Proper cooling: Cool large batches of soups or stews in shallow containers (no deeper than 2 inches)

- Cross-contamination prevention: Store raw meats below ready-to-eat TCS foods in refrigeration

- Staff training: Ensure everyone handling food understands TCS requirements (even in home settings with multiple cooks)

Remember that TCS food safety isn't about perfection—it's about risk reduction. The CDC reports that proper temperature control could prevent nearly 1 million foodborne illnesses annually in the United States alone.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4