Creating exceptional potato chips requires understanding both the science behind crispiness and practical techniques for consistent results. Whether you're making small batches in your kitchen or scaling up for commercial production, mastering the fundamentals of potato selection, slicing, frying, and seasoning transforms ordinary potatoes into irresistible snacks. This comprehensive guide reveals professional methods used by top producers while providing accessible techniques for home cooks.

The Potato Chip Production Fundamentals

Successful potato chip production begins with understanding the science of starch gelatinization and moisture removal. Potatoes contain approximately 70-80% water, which must be rapidly expelled during frying to create that signature crisp texture. The ideal frying temperature range of 350-375°F (175-190°C) triggers the Maillard reaction while minimizing oil absorption. Selecting the right potato variety with optimal sugar and starch content prevents undesirable browning during cooking.

Home Production: Step-by-Step Process

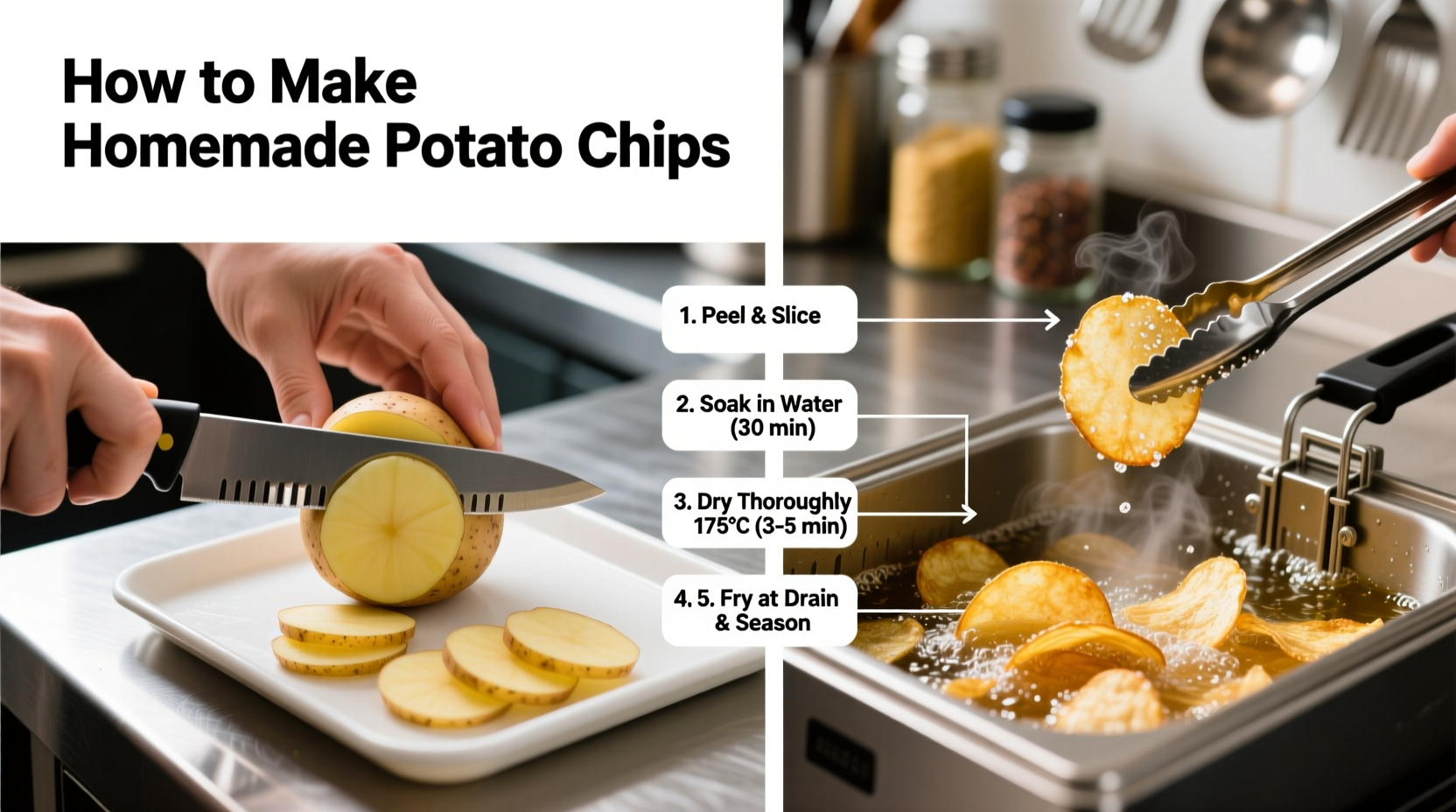

For home producers, achieving restaurant-quality chips requires attention to detail at each stage. Start with high-starch varieties like Russet Burbank or Yukon Gold potatoes, which yield the crispiest results. Peel and slice potatoes to a uniform 1/16-inch thickness using a mandoline slicer for consistency. Immediately submerge slices in cold water to remove excess surface starch, changing the water until it runs clear.

After a 10-minute soak, thoroughly dry slices with clean kitchen towels. Heat neutral oil with a high smoke point (like peanut or canola) to 365°F in a deep fryer or heavy-bottomed pot. Fry in small batches for 2-3 minutes until golden, stirring gently to prevent sticking. Remove with a slotted spoon and drain on paper towels before seasoning while still warm.

| Home Production Factor | Optimal Specification | Common Mistake |

|---|---|---|

| Potato Variety | Russet Burbank, Yukon Gold | Using waxy potatoes like red potatoes |

| Slice Thickness | 1/16 inch (1.5mm) | Inconsistent thickness causing uneven cooking |

| Frying Temperature | 365°F (175°C) | Temperature too low causing greasy chips |

| Drying Time | Complete dryness before frying | Moist slices causing oil splatter and sogginess |

Commercial Production Evolution

Modern commercial potato chip production has evolved significantly since George Crum's 1853 invention at Moon's Lake House in Saratoga Springs. Today's factories employ precision engineering to maintain quality at scale. The commercial process begins with automated sorting systems that reject imperfect potatoes based on size, shape, and defects. Potatoes move through industrial peelers using high-pressure water or lye solutions before entering multi-blade slicers capable of producing 3,000+ slices per minute.

After slicing, potatoes pass through centrifugal dryers removing surface moisture before entering continuous fryers with precisely controlled oil temperatures. Modern systems use counter-current frying technology where chips move opposite to oil flow, maintaining oil quality and reducing absorption. Automated seasoning drums apply precise flavor coatings before chips enter optical sorters that reject discolored or broken pieces. The entire process from raw potato to packaged product typically takes 15-20 minutes in contemporary facilities.

Quality Control Essentials

Maintaining consistent quality requires systematic monitoring at critical control points. Professional producers measure:

- Moisture content - Target 1-2% for optimal crispness and shelf stability

- Oil absorption - Industry standard is 30-35% by weight

- Color consistency - Using standardized color charts (L*, a*, b* values)

- Texture profile - Measuring fracture force and acoustic crispness

Food safety regulations require strict monitoring of oil quality parameters. The FDA recommends discarding frying oil when total polar materials exceed 25% or when smoke point drops below 400°F. Regular testing for acrylamide levels is essential, as this potential carcinogen forms when asparagine reacts with reducing sugars at high temperatures.

Troubleshooting Common Production Issues

Even experienced producers encounter challenges. Here's how to address frequent problems:

- Soggy chips - Usually caused by insufficient drying before frying or oil temperature dropping too low. Solution: Ensure complete surface dryness and maintain consistent oil temperature with proper batch sizes.

- Excessive browning - Often results from high sugar content in potatoes stored below 45°F. Solution: Store potatoes at 45-50°F and test sugar levels before production.

- Oiliness - Indicates oil absorption during cooling. Solution: Drain chips thoroughly and allow proper cooling time before packaging.

- Inconsistent seasoning - Caused by applying seasoning to insufficiently warm chips. Solution: Season immediately after frying when surface is still slightly moist.

Scaling Production Successfully

Transitioning from home to commercial production requires addressing several critical factors. Small-scale producers often underestimate the importance of humidity control in the production environment - ideal conditions are 50-60% relative humidity. Professional equipment investments should prioritize precision slicers and temperature-controlled fryers before considering automated seasoning systems.

For those exploring commercial production, the USDA Food Safety and Inspection Service provides comprehensive guidelines for safe food manufacturing practices. The Potato Council's research on optimal potato varieties for chip production offers valuable insights into selecting the right raw materials for consistent results. Understanding these fundamentals separates successful producers from those struggling with quality control issues.

What potato varieties work best for chip production?

Russet Burbank potatoes are the industry standard for commercial production due to their high starch content and low sugar levels. For home production, Yukon Gold offers excellent results with their balanced starch-sugar ratio. Avoid waxy potato varieties like red potatoes, which contain less starch and produce softer, less crispy chips.

How can I prevent my homemade chips from becoming greasy?

Greasy chips typically result from oil temperature dropping too low during frying. Maintain a consistent 365°F oil temperature using a reliable thermometer. Fry in small batches to prevent temperature fluctuations, and ensure potato slices are completely dry before adding to hot oil. Proper draining on wire racks (not paper towels) after frying also helps reduce excess oil absorption.

What causes potato chips to brown too quickly during frying?

Excessive browning occurs when potatoes contain high sugar levels, often from improper storage below 45°F. Cold storage converts starch to sugar, accelerating the Maillard reaction. Store potatoes at 45-50°F and allow cold-stored potatoes to temper at room temperature for 24 hours before processing. Blanching slices in hot water (170°F) for 5 minutes can also reduce sugar content.

How do commercial producers maintain consistent thickness in potato slices?

Professional facilities use precision multi-blade slicers with adjustable thickness settings, typically set to 0.010-0.015 inches. These machines incorporate vibration technology to prevent potato sticking and maintain consistent pressure against the blades. Quality control systems include automated optical measurement of slice thickness throughout production runs to ensure uniformity.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4