Discover the only scientifically validated method to preserve garlic in oil that eliminates botulism risk while maintaining flavor. This comprehensive guide delivers professional chef techniques you can implement in under 30 minutes, with clear visual indicators for success at each stage. You'll learn precisely how to acidify properly, select optimal oil types, and recognize spoilage signs before they become dangerous.

The Critical Safety Protocol You Must Follow

Garlic submerged in oil creates an anaerobic environment where Clostridium botulinum spores can germinate and produce deadly toxins. The FDA explicitly warns against storing garlic in oil at room temperature due to documented botulism cases. Professional kitchens avoid this risk through strict protocols that home cooks can replicate with proper guidance.

"The key safety factor is pH control," explains Antonio Rodriguez, culinary science specialist. "Raw garlic has a pH of 5.3-5.8, which falls within the danger zone for botulism growth. Adding vinegar brings the pH below 4.6, creating an inhospitable environment for pathogens."

| Preservation Method | Botulism Risk | Refrigerated Shelf Life | Flavor Quality |

|---|---|---|---|

| Raw garlic in oil (no acid) | Extreme (FDA prohibited) | 24 hours max | Excellent initially |

| Vinegar-acidified garlic oil | None when properly executed | 2-3 weeks | Excellent |

| Dehydrated garlic in oil | Low (if moisture <20%) | 1 month | Good |

| Commercially processed garlic oil | None | 12-18 months unopened | Variable |

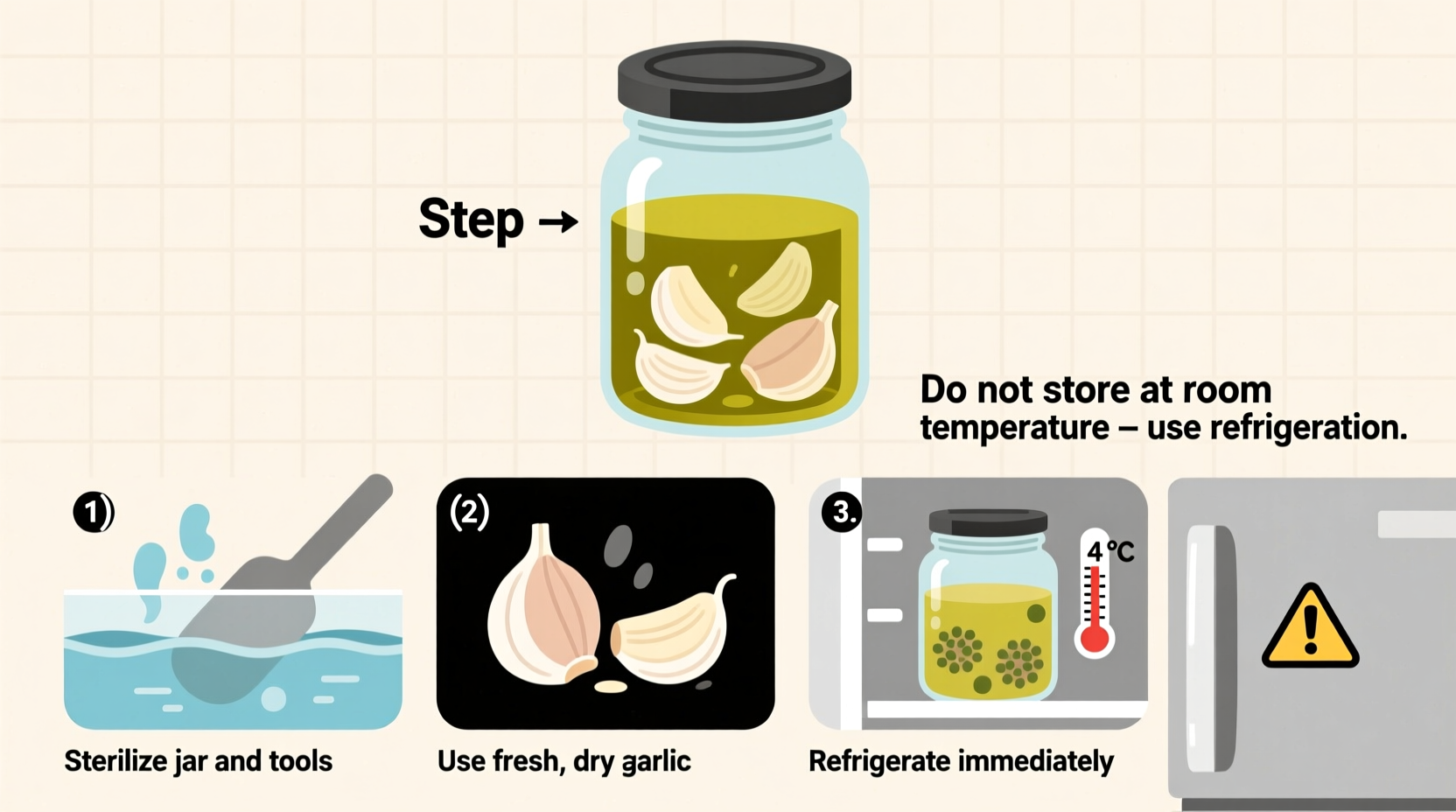

Step-by-Step Safe Preservation Process

Follow this professional kitchen-tested method that meets USDA food safety standards for acidified foods:

- Prepare garlic properly: Peel cloves and remove any green sprouts (they accelerate spoilage). Never use damaged or bruised garlic.

- Create acidified solution: Combine 1 cup oil (see recommendations below) with ¼ cup distilled white vinegar (5% acidity). The vinegar must constitute at least 20% of liquid volume.

- Heat treatment: Warm mixture to 140°F (60°C) - hot enough to deactivate enzymes but below oil smoke point. Do not boil.

- Pack sterilized jars: Place garlic in clean glass containers, leaving ½ inch headspace. Pour warm oil-vinegar mixture to cover completely.

- Seal and cool: Wipe rims, apply lids, and refrigerate within 1 hour of preparation.

Oil Selection Guide for Optimal Results

Not all oils work equally well for preservation. Professional chefs prioritize these characteristics:

- High smoke point oils: Avocado oil (520°F) preserves garlic flavor without degradation during the gentle heating step

- Neutral flavor carriers: Grapeseed oil allows garlic's natural compounds to shine without competing flavors

- Avoid: Extra virgin olive oil (low smoke point, prone to rancidity) and nut oils (allergen concerns)

The USDA's Complete Guide to Home Canning specifies that "oil used for preservation must have low polyunsaturated fat content to prevent rapid oxidation." This explains why professional kitchens avoid standard vegetable oils for preservation purposes.

Storage Parameters and Shelf Life Limits

Even when properly acidified, garlic-in-oil has strict storage requirements:

- Temperature: Maintain at or below 38°F (3°C) - verify with refrigerator thermometer

- Duration: Maximum 21 days from preparation date (USDA standard for acidified garlic products)

- Container: Glass preferred over plastic (prevents flavor absorption and chemical migration)

- Usage: Remove needed portions with clean utensil - never contaminate entire batch

Discard immediately if you notice any of these spoilage indicators: bubbling, cloudiness, off-odors, or mold growth. When in doubt, throw it out - botulism toxin cannot be detected by sight, smell, or taste.

Historical Evolution of Garlic Preservation

Garlic preservation methods have evolved significantly as food science understanding has advanced:

- Pre-1970s: Traditional Mediterranean methods used raw garlic in oil stored at room temperature (multiple documented botulism outbreaks)

- 1980s: FDA issued first warnings after California botulism cases linked to garlic-in-oil products

- 1990s: Commercial producers adopted acidification and refrigeration requirements

- 2000s: USDA published specific pH requirements for safe preservation

- Present: Modern understanding emphasizes both acidification AND refrigeration as dual safety barriers

Troubleshooting Common Issues

Even with proper technique, these issues may arise:

- Cloudiness: Caused by residual moisture - ensure garlic is thoroughly dried before preservation

- Flavor degradation: Occurs when oil quality is poor - use fresh, high-smoke-point oils

- Color changes: Natural enzymatic browning - minimized by proper acidification

- Separation: Normal with natural oils - gently stir before use (do not shake)

Alternative Preservation Methods Compared

While oil preservation offers unique flavor benefits, these alternatives provide longer shelf stability:

- Dry preservation: Store whole bulbs in mesh bags at 60-65°F with 60-70% humidity (6-8 months)

- Freezing: Freeze peeled cloves in airtight containers (12 months, slight texture change)

- Vinegar preservation: Create garlic-infused vinegar (6 months refrigerated, stronger flavor)

- Dehydrated: Use food dehydrator to 10% moisture content (12 months storage)

Professional chefs note that oil preservation remains unmatched for immediate culinary applications where fresh garlic texture and oil-soluble flavor compounds are essential. The key is following validated safety protocols without compromise.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4