Why Proper Frozen Food Shipping Matters

Shipping frozen food requires careful planning to prevent spoilage and ensure food safety. When temperatures rise above 40°F (4°C), bacteria can multiply rapidly, creating serious health risks. According to the USDA Food Safety and Inspection Service, "perishable foods like raw or cooked meat must be kept at 40°F or below during transit to prevent bacterial growth that can cause foodborne illness." Whether you're sending homemade treats, specialty foods, or business products, following proper frozen shipping protocols protects both your recipients and your reputation.

Planning Your Frozen Food Shipment: Critical First Steps

Before you start packaging, determine your transit time requirements. Most domestic shipments take 1-3 business days, but add buffer time for potential delays. The FDA recommends that frozen food should not be above 0°F (-18°C) for more than 2 hours during transit. Consider these key planning factors:

- Transit distance - Longer distances require more robust cooling solutions

- Seasonal temperatures - Summer shipping needs more cooling than winter

- Food type sensitivity - Some items (like ice cream) require stricter temperature control than others

- Recipient availability - Ensure someone can receive and immediately refrigerate/freeze the package

Never ship frozen food using standard ground shipping for more than 24 hours, as this significantly increases the risk of partial thawing. The USDA advises against shipping frozen food through the mail during extreme heat waves when ambient temperatures exceed 90°F (32°C).

Essential Packaging Materials for Frozen Shipping

Professional frozen food shipping requires specific materials that work together as a system. Don't substitute household items unless absolutely necessary—proper packaging is your first line of defense against temperature excursions.

Insulated Containers

Choose from these proven options:

- Expanded polystyrene (EPS) coolers - Most effective insulator (R-value of 5 per inch)

- Corrugated insulated mailers - Good for shorter shipments (1-2 days)

- Reusable thermal shipping containers - Cost-effective for businesses shipping regularly

Cooling Agents Compared

| Cooling Method | Duration at 0°F | Cost Range | Best For |

|---|---|---|---|

| Dry ice (solid CO₂) | 24-48 hours | $2.00-$3.50/lb | Long-distance shipping, temperature-sensitive items |

| Phase change materials | 36-72 hours | $8-$15/unit | Business shipments, consistent temperature needs |

| Reusable gel packs | 24-36 hours | $3-$6/unit | Shorter shipments, eco-friendly option |

| Homemade frozen water packs | 12-24 hours | $0.50-$1.00/unit | Very short shipments, budget option |

Temperature Monitoring

Include at least one temperature indicator in every shipment. The FDA recommends using time-temperature indicators that change color if temperatures exceed safe limits. These inexpensive devices (FDA Food Code, Section 3-501.16) provide proof that your food remained frozen during transit.

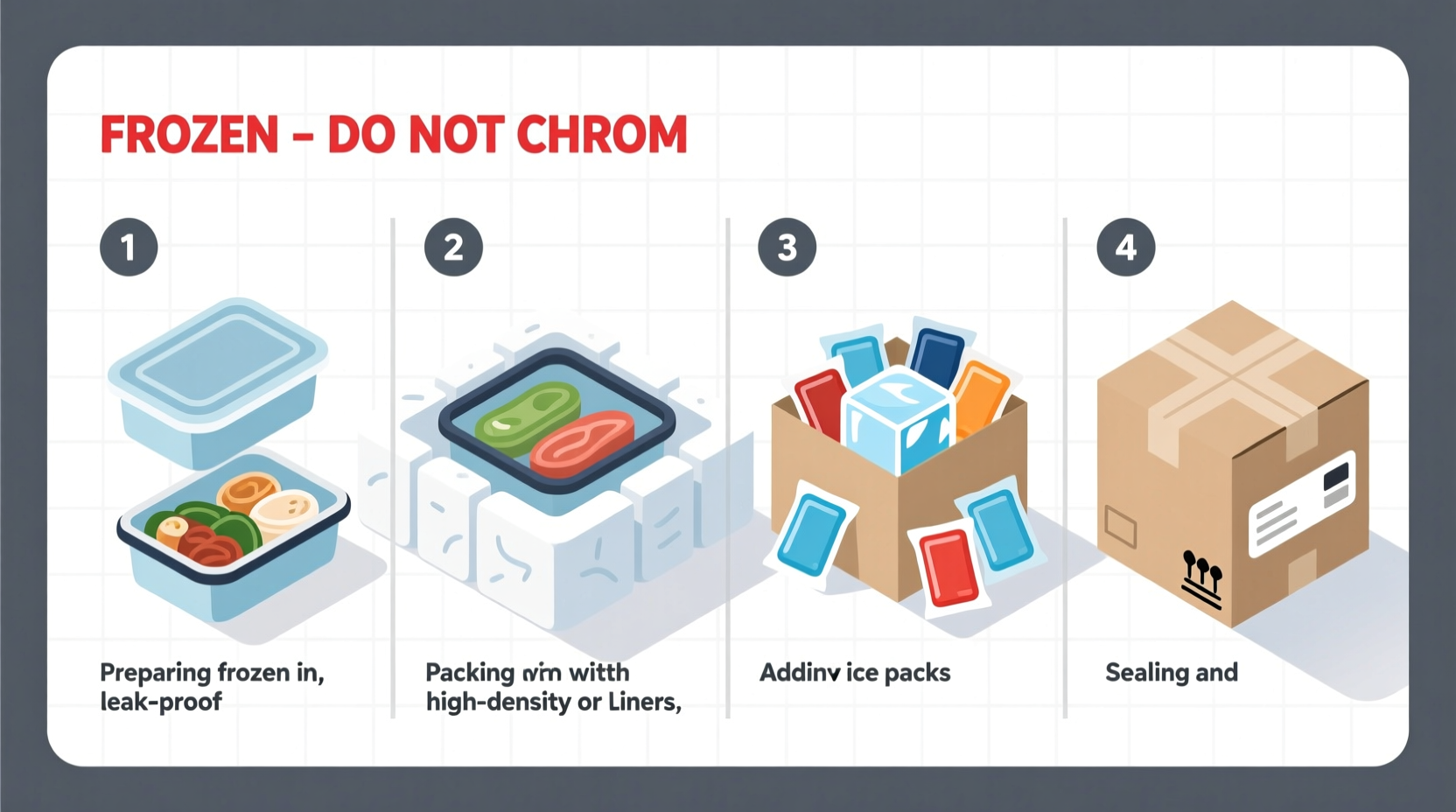

Step-by-Step Frozen Food Packaging Process

Follow this professional method used by food manufacturers to ensure your frozen items arrive in perfect condition:

Step 1: Prepare Your Food

Ensure food is completely frozen before packaging—ideally at -10°F (-23°C) or lower. Flash-freeze items on a baking sheet before packaging to prevent ice crystal formation. Place each item in airtight, leak-proof packaging to prevent freezer burn and contain any potential leaks.

Step 2: Layer Cooling Elements Strategically

Place cooling elements at the bottom, sides, and top of the container—not just on top. For dry ice shipments, use 5-10 pounds per 24 hours of expected transit time. Always separate dry ice from food with a barrier (like cardboard) to prevent freezer burn. The Department of Transportation requires dry ice shipments to have proper ventilation (49 CFR §172.102).

Step 3: Create a Temperature-Controlled Environment

Place your packaged food inside an insulated cooler with cooling elements. Add absorbent material around the food to contain any potential leaks. Seal the cooler with strong tape, then place it inside a sturdy corrugated cardboard box with at least 2 inches of space between the cooler and outer box for additional insulation.

Step 4: Finalize Shipping Documentation

Clearly label the package "PERISHABLE" and "KEEP FROZEN" on multiple sides. For dry ice shipments, include the required DOT label " dry ice" or "carbon dioxide, solid" and the net weight. Complete all required shipping documentation—carriers may refuse improperly labeled frozen shipments.

Shipping Carrier Comparison for Frozen Food

Not all carriers handle frozen shipments equally. Here's how the major options compare for frozen food shipping:

| Carrier | Best Service | Dry Ice Policy | Temperature Monitoring | Cost for 5lb Package (2-day) |

|---|---|---|---|---|

| USPS | Priority Mail Express | Allowed (max 5.5 lbs) | Basic tracking only | $32-$45 |

| FedEx | FedEx Priority Overnight | Allowed (proper labeling) | Optional SenseAware ($15) | $45-$65 |

| UPS | UPS Next Day Air | Allowed (max 5.5 lbs) | Optional Quantum View ($10) | $42-$60 |

| Specialty Carrier | Food-specific services | Expert handling | Real-time monitoring | $55-$85 |

USPS remains the most affordable option for small shipments but offers the least temperature control assurance. FedEx and UPS provide more reliable temperature-controlled options with better tracking capabilities. For high-value or temperature-sensitive items, specialty food shippers often provide the best protection despite higher costs.

Avoiding Common Frozen Shipping Mistakes

Even experienced shippers make these critical errors that compromise food safety:

- Insufficient cooling material - Using too few gel packs is the #1 cause of partial thawing

- Poor insulation - Thin containers lose cold temperature rapidly (test your container's R-value)

- Incorrect dry ice handling - Never seal dry ice in an airtight container (risk of explosion)

- Ignoring transit time - Choosing 3-day shipping for items requiring 2-day delivery

- Skipping temperature monitoring - You won't know if temperatures were maintained

The USDA reports that 68% of failed frozen food shipments resulted from inadequate cooling material for the transit duration. Always calculate your cooling needs based on worst-case transit scenarios, not best-case estimates.

Special Considerations for Different Frozen Foods

Not all frozen foods have the same shipping requirements. Understanding these differences prevents costly mistakes:

- Ice cream and frozen desserts - Require strict temperature control below -10°F (-23°C) to prevent texture changes

- Raw meats and seafood - Must remain frozen solid to prevent bacterial growth (USDA requirement)

- Baked goods - More tolerant of brief temperature fluctuations but vulnerable to freezer burn

- Prepared meals - Check for sauce separation issues when thawed and refrozen

When shipping across state lines, be aware of specific state regulations. Some states restrict certain food items or have additional labeling requirements. The FDA's Interstate Travel of Food guidance outlines these requirements (FDA Guidance).

What to Do When Shipping Delays Occur

Despite careful planning, shipping delays happen. Be prepared with these contingency measures:

- Include a note with recipient instructions: "If delayed, immediately freeze upon arrival even if partially thawed"

- Choose shipping insurance that covers temperature excursions

- Provide direct contact information so recipients can reach you with issues

- Consider adding a small amount of extra cooling material as a buffer

According to food safety guidelines, partially thawed food can be safely refrozen if ice crystals remain and the temperature hasn't exceeded 40°F for more than 2 hours. However, quality may be compromised.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4