The Science Behind Freeze Drying: More Than Just Removing Water

Understanding how freeze dried food works begins with the physical principle of sublimation—the process where ice transforms directly into water vapor without passing through the liquid phase. This phenomenon occurs under specific temperature and pressure conditions, which is why freeze drying requires specialized equipment that creates a vacuum environment while carefully controlling temperature.

Unlike traditional dehydration that uses heat to evaporate moisture (which can damage cell structures and degrade nutrients), freeze drying maintains the food's cellular architecture. When water freezes inside food cells, it forms ice crystals that create a scaffold-like structure. During sublimation, these ice crystals vaporize while maintaining this structure, resulting in food that rehydrates almost completely back to its original state.

Step-by-Step: The Freeze Drying Process Explained

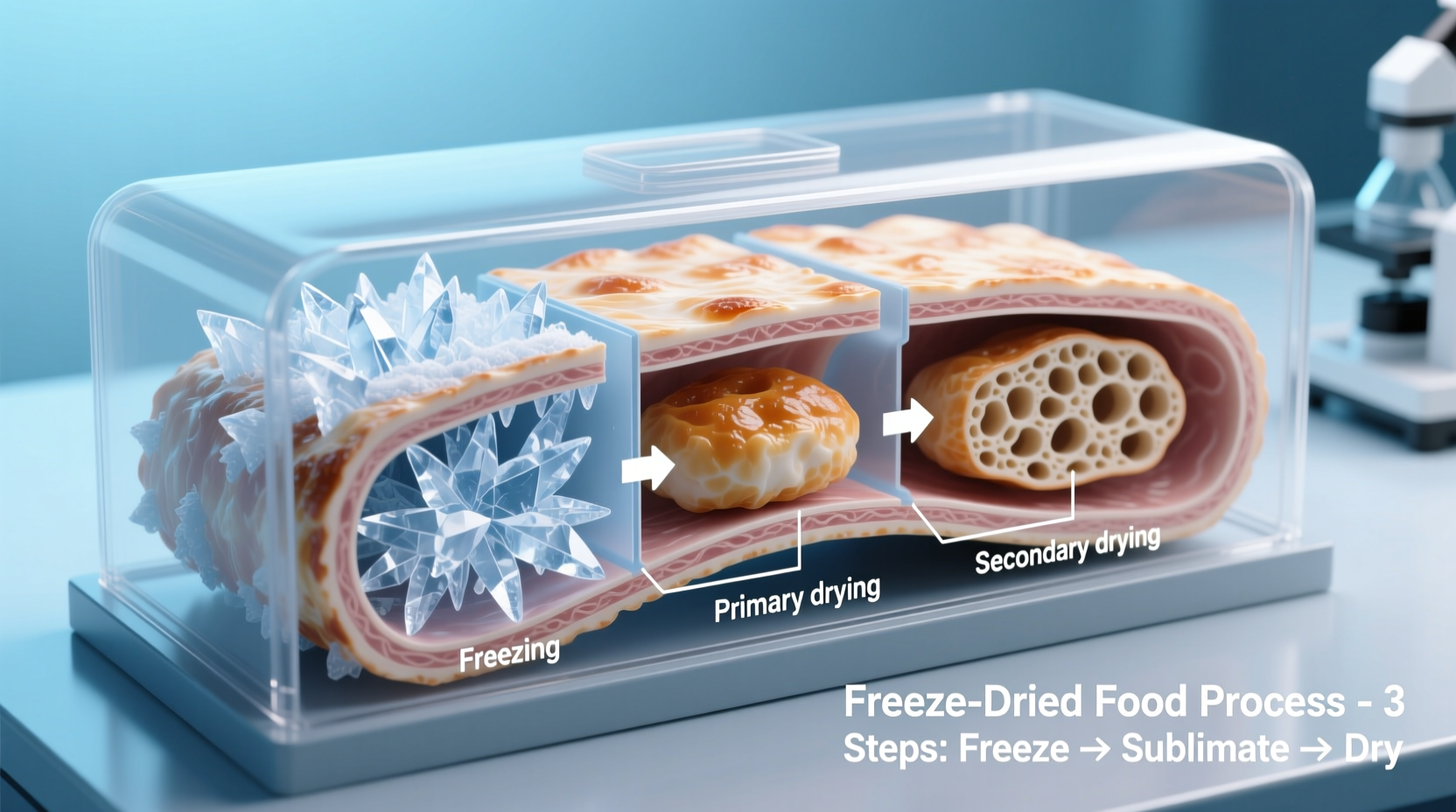

The freeze drying process consists of three scientifically precise stages that work together to preserve food while maintaining quality:

1. Freezing Stage: Creating the Structural Foundation

Food is rapidly frozen to temperatures between -40°F and -58°F (-40°C to -50°C). This rapid freezing creates smaller ice crystals that cause less damage to cell walls. The freezing rate significantly impacts final product quality—too slow creates large crystals that damage texture, while too fast may not freeze the core properly.

2. Primary Drying (Sublimation): Removing Bulk Moisture

During this critical phase, pressure is reduced to create a vacuum (typically 0.01-0.1 millibars), and gentle heat is applied. The vacuum environment allows ice to sublimate directly into vapor. This stage removes about 95% of the moisture and requires careful temperature control—too much heat cooks the food, while too little slows the process. The sublimation front moves from the surface toward the center, taking anywhere from 10-40 hours depending on food type and thickness.

3. Secondary Drying (Desorption): Eliminating Bound Water

The final stage targets residual moisture molecules bound to the food's structure. Temperature is gradually increased (typically to 95-140°F or 35-60°C) while maintaining vacuum conditions. This carefully controlled heating releases bound water without damaging the food's cellular structure. Proper secondary drying reduces moisture content to 1-4%, creating the optimal environment for long-term preservation without spoilage.

How Freeze Drying Compares to Other Preservation Methods

Understanding how does freeze dried food work requires comparing it to alternative preservation techniques. Each method affects food differently based on the scientific principles involved:

| Preservation Method | Temperature Range | Moisture Removal | Nutrient Retention | Rehydration Quality |

|---|---|---|---|---|

| Freeze Drying | -58°F to 140°F (-50°C to 60°C) | 95-99% via sublimation | 97%+ of original nutrients | Nearly identical to fresh |

| Dehydration | 120°F to 160°F (49°C to 71°C) | 80-95% via evaporation | 60-80% of original nutrients | Altered texture and flavor |

| Canning | 170°F to 250°F (77°C to 121°C) | None (liquid medium) | 40-60% of original nutrients | Cooked texture, altered flavor |

| Refrigeration | 32°F to 40°F (0°C to 4°C) | None | Gradual nutrient loss | Fresh quality (short-term) |

This comparison shows why freeze drying preserves food structure better than other methods. According to research from the National Center for Home Food Preservation, freeze dried foods retain up to 97% of their original nutritional content compared to 60-80% for dehydrated foods and 40-60% for canned foods. The low-temperature process prevents the Maillard reaction and enzymatic browning that degrade quality in heat-based preservation methods.

Practical Applications and Real-World Benefits

Understanding how freeze dried food work reveals why it's become essential across multiple industries. The military, space programs, and emergency preparedness organizations rely on freeze dried foods because they maintain nutritional value while dramatically reducing weight and volume. A study by NASA confirmed that freeze dried foods retain their nutritional profile during extended space missions, making them ideal for astronauts.

For outdoor enthusiasts, the lightweight nature of freeze dried meals (typically 70-90% lighter than fresh equivalents) makes them invaluable. Backpackers can carry weeks of nutrition in minimal space. The food industry uses freeze drying for premium ingredients like coffee, fruits, and dairy products where flavor preservation is critical. Pharmaceutical companies apply the same principles to preserve vaccines and medications that would otherwise degrade.

Limitations and Appropriate Use Cases

While freeze dried food offers remarkable benefits, it's not universally appropriate. The process works best with foods that have high water content and stable structures—fruits, vegetables, meats, and prepared meals. Foods with high oil content (like avocados or olives) don't freeze dry well because oils can become rancid during storage. Similarly, foods with high sugar concentration may melt during the process.

According to the USDA's Food Safety and Inspection Service, proper storage is critical for maintaining freeze dried food quality. Even with moisture content reduced to 1-4%, exposure to humidity can cause reabsorption and spoilage. The ideal storage conditions are cool, dark places in moisture-proof containers with oxygen absorbers. Under these conditions, properly freeze dried foods can maintain quality for 25-30 years, significantly longer than dehydrated foods (typically 5-10 years).

Historical Development of Freeze Drying Technology

The science behind how freeze dried food work has evolved significantly over time. While indigenous peoples in the Andes Mountains naturally freeze dried potatoes (chuño) by exposing them to freezing nights and sunny days, modern freeze drying technology emerged during World War II when blood plasma and penicillin needed preservation for battlefield use. NASA's space program in the 1960s drove further innovation to provide astronauts with nutritious, lightweight food. Today's commercial freeze dryers use sophisticated computer controls to optimize the process for different food types, making the technology accessible to home users with countertop units.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4